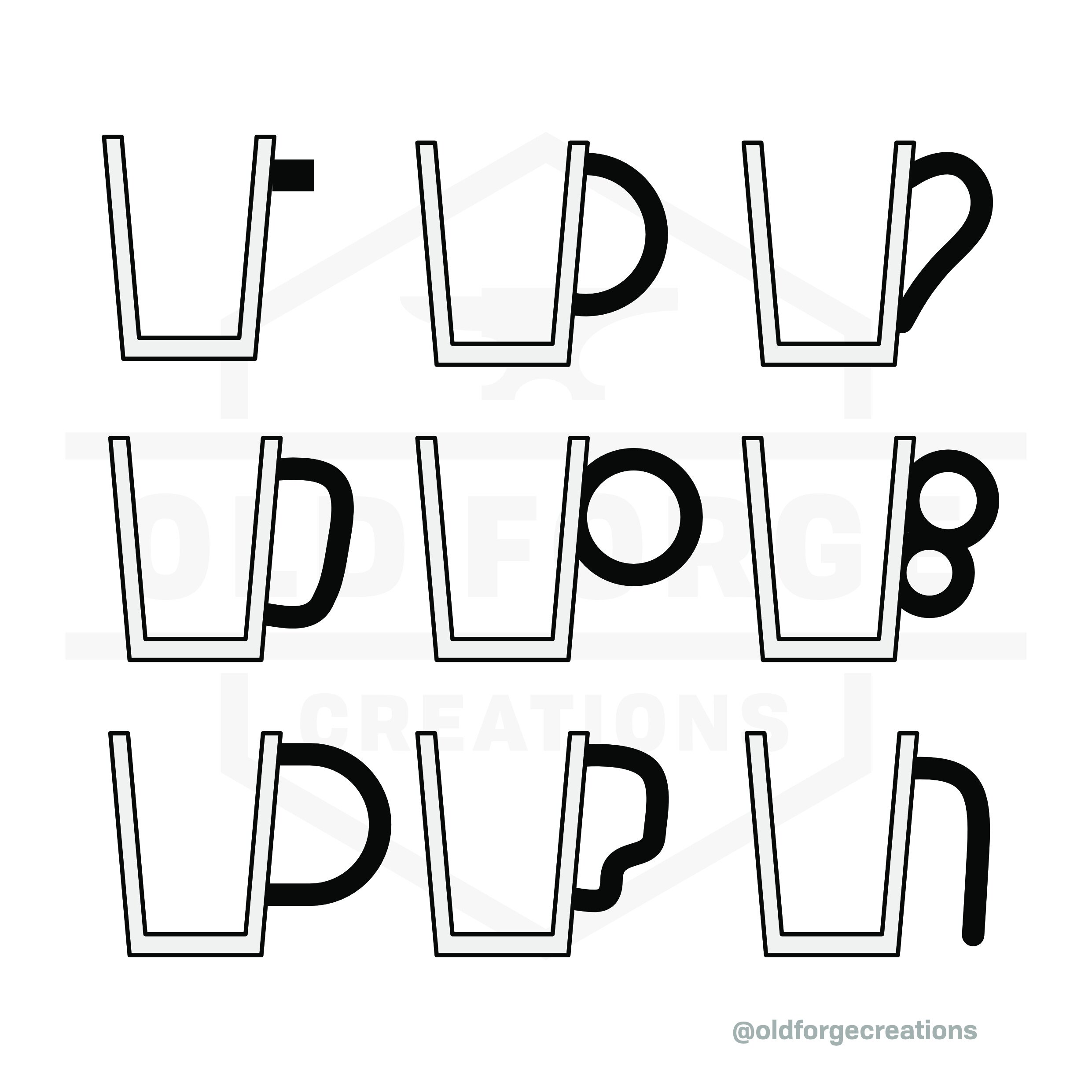

Easy Handles

Edit Aug 2021: The process I use has evolved since writing this. I’ll leave the rest of the post up as it was, but a more complete guide to my process now can be seen in this video:

I use a handheld extruder to make my handles. It's quick, easy, and consistent.

Handles can be very tricky, and can be a sticking point. I avoided making mugs for far too long, purely because I couldn't make a handle I liked.

This is a guide to show I make my handles now. It's a very simple approach, but it produces consistent and comfortable handles.

The first step is to make the piece you'll be attaching the handle to, and letting it dry to an even leather hardness. With the exception of the Drippy Slippy pieces, I throw the pieces the day before. They sit overnight in a sealed plastic box to even out, and the handles get attached immediately after trimming the foot.

The trick to this approach is using an extruder (I use this) to produce a strap of clay.

You'll probably have to make your own die, but some extruders will come with appropriate dies. I made mine by drilling two 7mm diameter holes and removing the metal between them to make a rounded rectangle approximately 15mmx7mm.

Use your extruder to produce a length of clay, and cut this into smaller sections. You'll need to make a few to get a feel for what length you need for different pieces, but as an example, I use 105mm lengths for my medium mugs.

Once I've cut a section, I use my ever-useful grinding bit (see the Peacock Eye how-to) to flare and texture the end. This gives a small taper and slightly more surface area for the join.

Then bend at what you feel is the right distance out.

Repeat at the other end, and you've got a handle. Set these aside for as long as your clay needs to firm up to match the dryness of the piece. This is important to avoid cracking as they dry. As with everything in ceramics, it's a case of juggling the timings. I extrude my handles, then trim the feet of a batch of mugs, and (weather depending) the handles are generally about dry enough after that. You'll have to find what works for you.

Next step is to score the piece. I've drawn a ruler on my hedgehog rib, it makes this stage much easier. Your handles are already made, so you can measure them to see what distance apart you need to score the piece.

Apply slip to both sides of the joint. I make my slip by adding a little water to dry trimmings of the same clay I use for the piece and handle.

Support the mug on the inside of the join and push the two together firmly.

Finally, I smooth and compress the join with a rounded silicon smoothing tool. Don't leave it too long before doing this or the slip will become too solid.

Then they dry slowly in plastic boxes over the next week or so. They need to dry evenly to avoid the handle cracking and potentially falling off, and the easiest way to ensure that is to dry them as slowly as possible.

That's all there is to it! Please try it and let me know how you get on, message me or use the hashtag oldforgecreations (I often miss @mentions on Instagram and there's no way to find them afterwards, but I'll see the tag). Good luck!