Top 10 Glaze Tips

Glazing is my favourite part of the process (by which I mean developing and testing glazes, the actual dipping and pouring is less interesting) but I know a lot of potters dread it. It’s understandable, it’s the final stage in a long process and can easily ruin weeks of work. There’s no magic cure for that, ceramics can be harsh and unforgiving, but there are ways to make the most of your glazes.

Here are my top 10 tips for getting to grips with your glazes. The real trick to enjoying glazing is loving (or at least, not hating) the results you get, and a lot of that is just not inadvertently messing it up:

Test. Test. Test.

Pay Attention To Thickness

Weigh The Application

Understand Your Glazes

Make The Most Of Tests

Don’t Rush

Be Consistent

Prepare Your Bisqueware

Let Them Dry

Use Drip Catchers

Test. Test. Test.

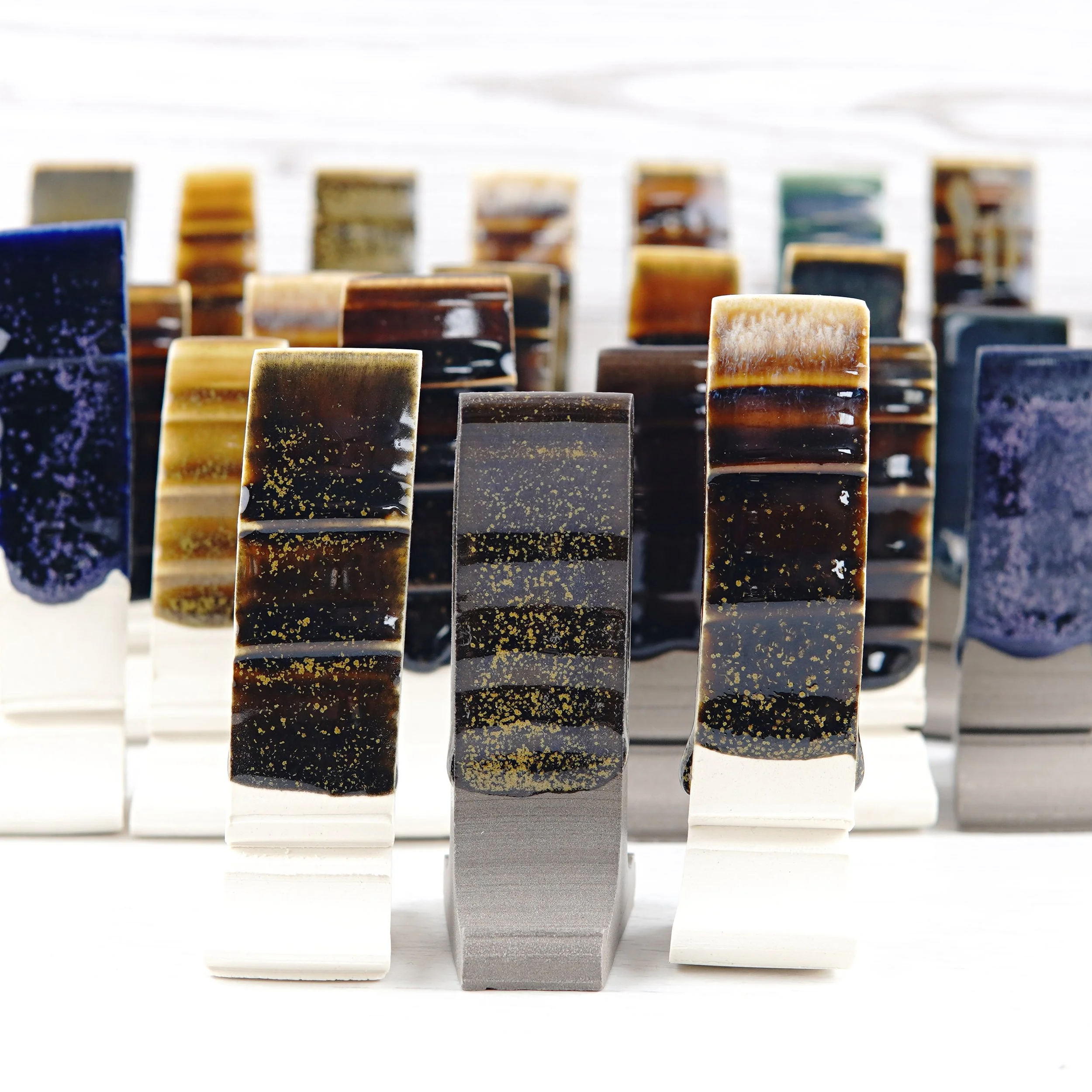

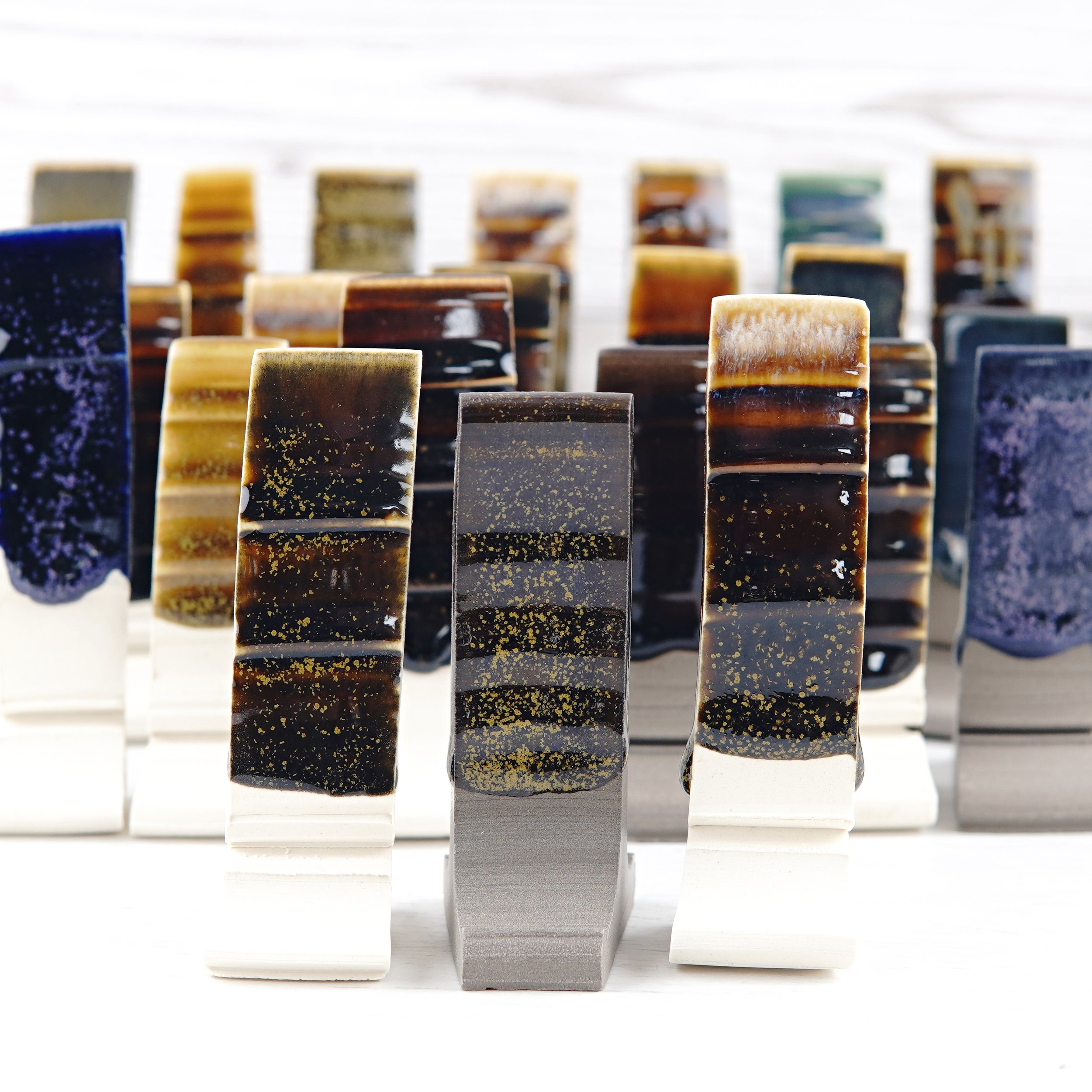

There is no substitute for time spent testing. Depending where you are on your glazing journey, this could mean a variety of different things. If you’re using premade glazes, whether bought or from a shared studio, then you still have a variety of thing you can find out. You ideally should know:

What each glaze looks like at various thickness. Some glazes are totally different at different thicknesses, some are identical. You need to know if a glaze result requires a certain application.

How a glaze changes over smooth and textured surfaces. This matters less if you only ever use one surface type, but knowing how behaviour changes between a ribbed smooth , lightly textured, or heavily textured/stamped/slipped surface will give a lot of information about the glaze.

What a glaze will look like over various clays/slips/underglazes (if you use them). Some glazes will totally change over different coloured clay. A thinner application of the Floating Blue recipe I use will be very sensitive to the clay it’s on, and it’s good to know that when applying it. I don’t like the colour as much over white clay so I make sure to apply it thicker, but love a thin application over black slip/underglaze.

What the glazes do in combination. It’s not always what you think! It’s nothing like mixing paint, if they merge together you’re combining two recipes to come up with a totally new one, and if they stay separate then you can get things like oil spot patterns where the physical movement of one glaze in the firing will create an entirely new pattern. Test a glaze over and under another glaze to see what works best.

If you use oxide washes, test the glazes over those too. This is similar to combining glazes, but generally more straightforward.

Kiln location. It’s not usually a factor, but if the glaze responds to slow cooling then placement can totally change the result.

What glazes do at different scales. Going from a test tile to a full piece isn’t always as straightforward as it should be. Test at a larger scale before committing to a full batch of a glaze.

And if you’re wondering whether you should be buying premade glazes or mixing your own, the simple answer is to do what’s right for you. Making your own has a bunch of advantages in the long run, but there are plenty of great reasons to use premade. If you want to make your own but don’t know where to start, I’ve got you covered. If you want interesting premade glazes, check out Midnight Ceramics.

If you make your own glazes but you’re not comfortable with the chemistry, then you can try removing the colourant(s) and swapping them for others. Again, this isn’t like mixing paints, you might find it does something unexpected. It will probably change other aspects of the behaviour too, so treat it as an entirely new glaze if you do this.

And after all the testing, put all but the best tiles aside for reference later, and only continue with a tiny percentage of them. Curation is just as important as testing.

Pay Attention To Thickness

Depending on the glaze, this can be the most important factor to getting the results you want. Clear glazes generally benefit from being thin to limit cloudiness and bubbles. Opaque glazes of a single colour can be thick or thin depending on how much you want the clay to show through. Where it becomes crucial is with layered flowing glazes. If you apply these too thinly you probably won’t get the colour or movement you’re looking for.

One thing you will almost certainly encounter if you try to apply multiple layers of glaze thickly is that there can be a tendency towards cracking and peeling off as the glaze dries. This usually results in crawling when fired, which is where patches of the clay are left exposed as the glaze pulls away. If you have this issue with a thin layer of a single glaze, then there are ways to fix it. It’s caused by excessive shrinkage as the glaze dries, and this can be reduced by using less water (and possibly deflocculating the mix to keep it fluid) and/or using calcined clay in place of a portion of the clay in the recipe. However, even if your glazes are perfectly happy going on in a single thick application, when combined in a thick layered application you can often have issues.

I get around this by applying my flowing glazes a little thinner initially, then coming back the next day and brushing a little more glaze on to key areas to get the movement. I find this is far less likely to cause crawling, although it will vary between glazes and might not work as well for you.

It is (sometimes) possible to bisque fire the first glaze before applying the second. It requires another firing, but this way the first glaze is permanently fused in place and cannot crawl. This only works with glazes that have the right amount of melt at whatever bisque temperature you use. Just glaze a piece as you normally would and put it into your usual bisque firing (check each glaze with test tiles first though). If it works correctly then the glaze will be fused into place but still be porous, allowing for a second glaze to be applied as normal. This technique is also useful if you want to build up a glaze to a thickness that would be a problem otherwise. Some glazes will want to be fused at a temperature lower than your bisque, and you can get interesting results by fusing at the higher temperature.

Weigh The Application

Following on from the previous tip, the easiest way to measure how much glaze is being added in a test or on a full piece is to weigh it before and after the application. Dipping time on it’s own is a fairly meaningless number, especially when comparing your application and results to someone else’s. If you’re going to pay attention to one number when testing glazes, weight of application is the one to track.

In either case, you want to zero a set of scales to the weight of the piece/test tile before adding the glaze, then weigh and record the weight after glazing. This works for dipping, pouring, or brushing a glaze (although if brushing a full piece, you might want to just record the start and end weight separately in case the scales time out before you finish). You do need to know how much water is in the glaze mix, but you should keep track of that anyway if you want predictable results.

You don’t need to do this for every piece (although it only takes a couple of seconds, so is probably worth the effort), but knowing what the right application weighs will be invaluable if you start having issues with consistency.

Understand Your Glazes

As per the first section, understanding your glazes comes in several layers. At the basic end you just want to understand how your glazes (bought or made) behave in various different conditions. That will get you a long way, but comes with limitations. The next stage is to understand the chemistry that the glaze recipe represents, as that’s all a ceramic recipe really is at the end of the day. The chemistry determines the behaviour, and the recipe is one of many ways to achieve that chemistry. By understanding what each ingredient brings to the mix, you can start to understand why recipes produce the results they do, and how to adjust them to change the characteristics.

I honestly can’t recommend the CMW classes highly enough for really getting to grips with the chemistry of the glaze ingredients. You can use offer code oldforgecmw for 25% off the Cone 6 course, which is an excellent starting point for getting deeper into understand what each ingredient does.

Whatever level you’re at with glazing, keeping detailed notes will really help you build a relationship with your glazes. It doesn’t guarantee that you won’t have issues with them, but will be invaluable when it comes to solving them.

Make The Most Of Tests

You can fit a lot more than one test on a test tile. Ideally you want to know how a glaze behaves over all the conditions you’d usually use it, so over smooth and/or textured surfaces, over the base clay and over underglaze/slip/oxide washes, or whatever makes the most sense for your processes. You can add several of these to the same test tiles.

I smooth one side of mine with a rib and add bands of slip to see how it behaves over both surface types. I add my coloured slip to the reverse side to see how the glaze behaves over different base colours. This allows me to get several tests in one, and it only takes a moment to add these aspects when throwing tiles on the wheel too.

Don’t Rush

Easily overlooked when a deadline is looming, but it’s almost never worth rushing. Whether that’s glazing a full kiln load in a relatively untested glaze and hoping there are no issues, trying to get a single piece glazed and straight into a firing, or mixing a batch of glaze when you don’t have the time or mental space to check as you go. I find I regret it more often than I don’t.

On a similar note, don’t use untested combinations on pieces you like! I know it’s tempting, you have a unique piece and you think you can make it even better by using a new combination of glazes that work perfectly in your head. I’ve done it so many times, and I’ve always regretted it.

Be Consistent

Applying glaze is only a small portion of glazing, there are several other aspects that it’s important not to overlook if you want consistent results.

Bisque firing temperature. The temperature you fire to will affect the porosity of your bisqueware, and it will affect each clay differently too. This is less of an issue if you weigh the glaze application, but if you dip for a given time, the bisque temp can drastically affect how much glaze is taken up.

There’s no ‘right’ bisque temperature, but keeping yours consistent will make it much easier to get a consistent glaze application.

How you prepare glazes. Some ingredients (e.g. tin and titanium) will tend towards clumping even though they are produced as a very fine powder. A high speed immersion blender is a great way to thoroughly mix up glaze test without sieving, but is powerful enough to break the tiny clumps up far more than slower speed mixing and sieving. This changes how the materials behave in the glaze and can give a totally different result, meaning an immersion blended test won’t necessarily give the same result when scaled up and mixed differently.

The best way around the issue is to either never use an immersion blender or always use an immersion blender. It only matters on the ingredients that are sensitive to it. These can be blended separately and added to a larger batch, to avoid burning out a motor blending a large batch of glaze.

Prepare Your Bisqueware

Try to avoid handling the area that will be glazed, especially with dirty/oily hands. Clean off any dust before glazing. I wipe everything with a damp sponge before glazing. Oil or dust can work almost like a resist, preventing the glaze from sticking to the pot and potentially causing crawling.

Check for sharp points - Slightly contradictory to the previous point (just make sure your hands are clean first!), run your hands over the rim and handle before glazing. Any sharp points should be sanded off before glazing. Don’t ignore them, they’ll ruin the piece and can’t be fixed after glazing. It’s even better to get in the habit of also checking this before loading a bisque kiln, as it’s so much easier to remove sharp points on greenware than bisqueware.

Let Them Dry

Let the pots dry overnight before firing if you can. Water in the kiln is never a good thing. Especially if it’s still in the piece when the temperature starts getting hot, as the steam leaving the piece can increase the likelihood of issues like crawling. I leave pieces overnight and have an hour hold at 100c at the start of every firing to fully dry out everything.

Use Drip Catchers

Finally, fire anything you think might run (and assume any untested glaze will run) on something that will protect your shelves. Even better, use something with a raised centre (like my wheel thrown drip catchers) which allows for a little more glaze movement without sticking. It allows you to take slightly more risks with your glazing without ruining pieces or shelves.

And as a bonus suggestion, try using a Car Dent Puller if you dip your glazes:

Another topic I considered including in the list is how to fix crazing. In the video below, Matt from Ceramic Materials Workshop explains why glazes craze, and how to adjust them to stop it from happening. The reason I’m not including it as a point above is because you usually can’t fix crazing and have the same glaze. The process of adding more glass formers to reduce crazing will change the behaviour of the glaze, and in a lot of cases that means you’re getting a different result. If you have a Floating Blue recipe that crazes on your clay body and you try to solve it by adjusting the glass formers, your glaze will stop floating in the same way. If you have a microcrystalline glaze (which often have low glass formers and craze as a result), increasing the glass formers will decrease or prevent crystal growth.

If you’re starting out with a new glaze than this is an easy way to adjust it to work perfectly for you. If you have a glaze you already like the appearance of, then it can be a much harder thing to get right.

Crazing is a clay:glaze fit issue, changing your clay can often be an easier fix.

Suggestions from Instagram

I asked for glazing tips on my Instagram stories and on Reddit, here’s a few of the top suggestions.

Document everything you do.

Dilute wax resist with water, it goes on much easier and does a better job of letting the glaze run back off.

Make doubly sure there’s no glaze on the bottom of the piece.

Use a piece of wet carpet to clean glaze off the bottom of dipped pieces.

Have a plan before you start!

It’s best to clean glaze splashes/mistakes off when they’re dry by scraping, rather than trying to do it while they’re still wet.

Always try to get at least one experiment into every kiln load.

Wax resist on the wheel rather than freehand.

Remix if you’ve been using a glaze for a little while, it will separate back out over time.

Try to keep an open mind when evaluating results. Give yourself the evening and sleep on it. Tiles look different the next day.

If your glaze hard pans, it's not worth it to use it. Spending 20 minutes mixing it up to dip a piece that doesn't turn out well because you still didn't get everything stirred up is a waste of time and kiln space.

If there’s anything you’d add to the list, please leave it in the comments below!

If you like this sort of content and want to support the creation of more, I now have a Patreon specifically for it or a page on my website if you just want to make a single donation.